What is AES?

What is AES?

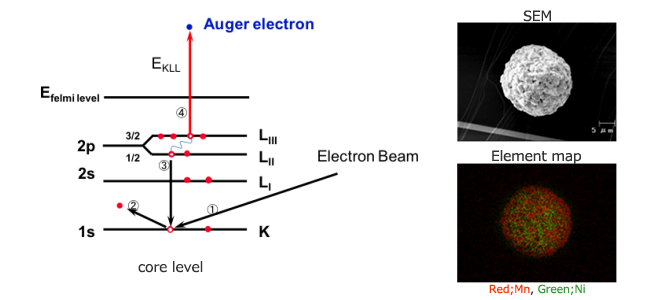

Principle

Auger Electron Spectroscopy (AES) is a technique for analyzing the element constituting the sample surface, its composition, and chemical bonding state by irradiating a focused electron beam on the sample surface, and measuring the kinetic energy of the Auger electrons emitted from the sample surface. Since the Auger electron energy emitted from the sample has a value specific to the element, the element on the sample surface can be identified by measuring the electron energy. Since Auger electrons lose energy as they pass through a sample, the analysis target for Auger spectroscopy is limited to several nms from the sample surface.

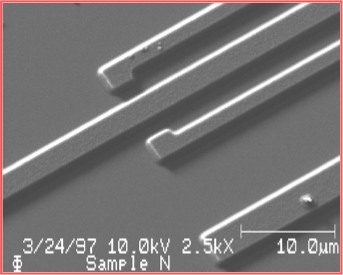

The irradiated electron beam can be focused to 5 nm or less, allowing for an ultra-microscopic area of the sample to be analyzed.

Excitation source (FE electron gun)

The excitation source used for Auger electron spectroscopy is the same heated Field Emission (FE) electron source used for SEM. The FE electron source focuses the electron beam diameter on the sample to 5 nm or less, enabling high current density.

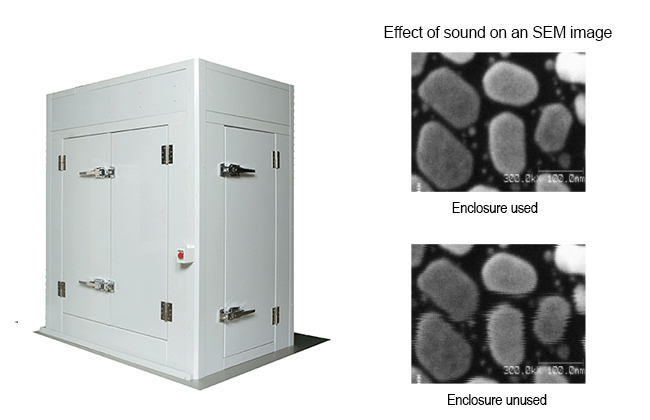

Enclosure

In order to analyze microscopic areas 5 nm or smaller, the electron beam must be applied steadily and continuously at one area of the sample. For that reason, Auger spectrometers measuring microscopic areas are equipped with enclosures that shut out vibrations from external sounds (sound pressure) and temperature changes.

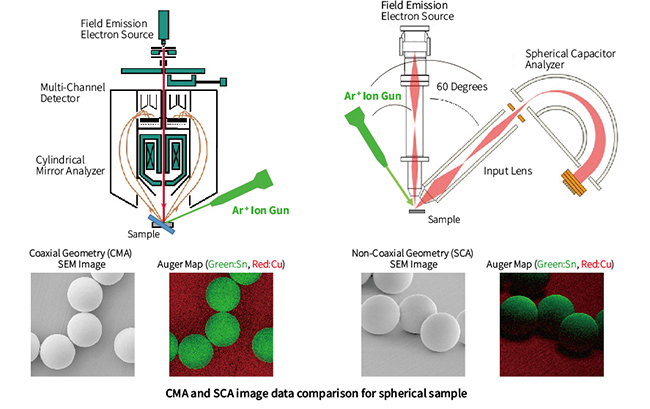

Detection system (Electron gun coaxial CMA electron analyzer)

The Cylindrical Mirror Analyzer (CMA) electron analyzer used as the Auger electron energy analyzer can be equipped with an electron gun along its central axis. By using this coaxial electron gun with the CMA electron analyzer, emitted Auger electrons can be detected from 360 degrees around the sample, enabling measurement of samples with uneven and complex shapes without shadows.

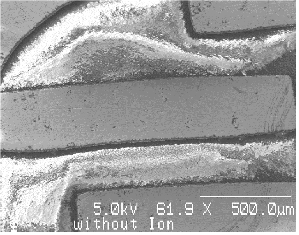

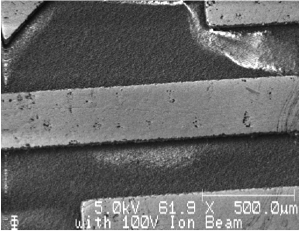

Charge compensation mechanism (argon ion neutralization)

Auger electron spectroscopy uses negatively charged electrons in the incident beam, so a negative charge builds up in the measurement location when measuring insulators and it must be neutralized. By irradiating the measurement location with low-speed argon ions (positive charge) from the argon ion gun, the charge on the sample can be eliminated, enabling Auger measurement on insulators.

a) |

b) |

a) SEM image showing intense charge build up when ion neutralization is not utilized.

b) SEM image when ion neutralization is utilized.

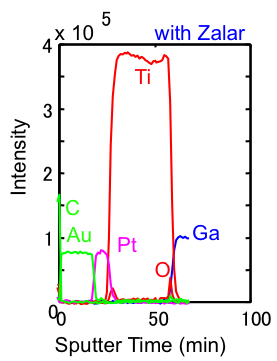

Depth profile analysis (argon ion gun)

Since the information depth measurable with Auger electrons is in the range of several nms from the surface, when the surface contamination layer is thick, or when evaluating a deeper area, ion sputtering is used to perform surface etching. An element composition depth profile can be obtained from the spectrum information gained through alternating between sputtering and measurement. Depth profiles are used for film thickness evaluation of samples with a multilayer structure and cause analysis for discoloration/corrosion of metal. Argon (Ar) ions are generally used for Auger depth profile analysis.