Semiconductor

2015.03.31 Update

Semiconductor

Semiconductor chips consist of a series of thin films that have been patterned to produce electronic devices. The use of surface analysis instruments to characterize the composition of thin films or patterned structures and detect contaminants or process residues is critical to the development of new materials, manufacturing processes, and increasing product yield.

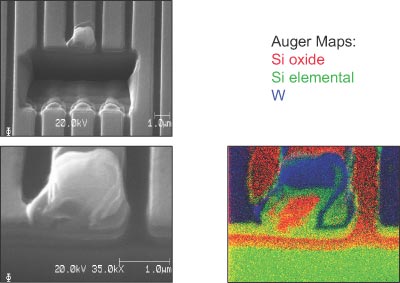

Defect Identification (AES)

The ability to identify the composition of nano-scale defects and determine their source of origin is critical to enhancing device yield. The continued shrinking of device size and critical defect size has limited the usefulness of optical methods and EDX analysis for sourcing ultra thin and ultra small defects. The PHI 700 Auger Nanoprobe is ideally suited for this application.

Fig. 1: A 50 nm diameter defect is confidently identified as being composed of aluminum.

Fig. 2: A buried defect, exposed by a FIB cut, was found to be a silicon dioxide particle encapsulated in silicon. It appears that the particle was formed during polysilicon and tungsten processing.

Trace Metal Contamination (TOF-SIMS)

Low level metal contaminants can have a serious impact on semiconductor device performance. The Patented TRIFT analyzer used in PHI’s TOF-SIMS surface analysis instruments provides a low spectral background and high mass resolution to provide the highest sensitivity and confident identification of trace level metal contaminants.

Fig. 3: In the example shown above the mass 56 peak has been analyzed with a mass resolution (m/Δm) of greater than 15,000 revealing metal and organic contaminants that are present at the same nominal mass as 28Si2+.

Ultra Shallow Implant Depth Profiling (D-SIMS)

Ultra Shallow implants are routinely used to create junctions for today’s high performance devices. PHI’s dynamic SIMS surface analysis instrument, the ADEPT-1010, provides a stable automated measurement platform for monitoring shallow implant processes.

Fig. 4: Shown above is the depth profile of a 500 eV boron implant obtained using a 500 eV oxygen sputter ion beam.

Bond Pad Surface Composition (XPS)

The composition and chemistry of bond pad surfaces influences device lifetime, physical, and electrical properties. For this reason many manufacturers of semiconductor devices monitor bond pad composition with PHI’s Quantera XPS surface analysis instrument. The Quantera provides high sensitivity micro-area XPS spectroscopy capabilities for monitoring the composition of small patterned features such as bond pads.

Fig. 5: XPS spectra obtained from aluminum bond pads show the presence of a surface oxide film and a fluorine containing contaminant. High fluorine concentration has been linked to corrosion and growth of oxide thickness at the surface of the aluminum bond pads.