Materials Research

2015.03.31 Update

Materials Research

Many basic materials are engineered to provide enhanced physical properties. Metal alloys, glasses, ceramics, and polymers often contain micro-phases and internal boundaries. The composition and distribution of these micro-phases have significant impact on the performance of the end product.

Grain boundary segregation (AES)

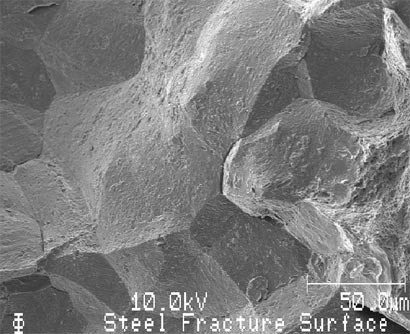

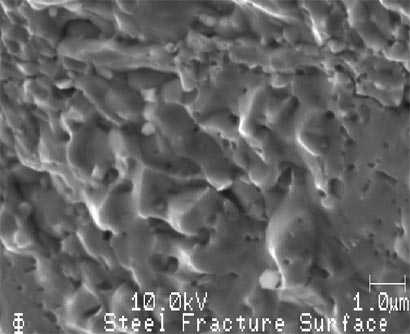

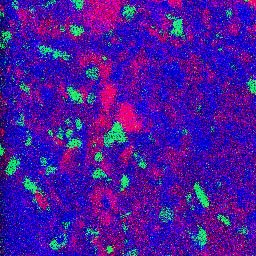

In situ fracture analysis can be used to probe grain boundary surfaces and detect elements that have segregated to the grain boundary or formed small precipitates. In the example shown below, a segment of a steam turbine blade was fractured under UHV conditions and the grain boundary surfaces were characterized with PHI's Auger Nanoprobe surface analysis equipment.

Fig. 1: Low magnification secondary electron image of a steel fracture surface.

Fig. 2: High magnification secondary electron image of a steel fracture surface

Fig. 2: Elemental AES images showing the grain boundary surface to be decorated with an antimony segregant and chromium carbide precipitates. (Iron Matrix, Chromium carbide precipitates, Antimony segregant)

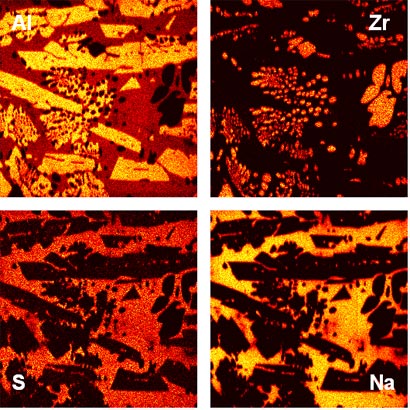

Detection of micro phases in ceramic materials (TOF-SIMS, AES)

Many ceramics are mixtures of materials that form localized compositional phases. The size and composition of these phases has a significant effect on the physical properties of the ceramic. TOF-SIMS provides the ability to image and characterize the individual phases as shown below.

Fig. 2: TOF-SIMS images of an alumina-zirconia-silica (AZS) ceramic material showing alumina and zirconia rich phases in a silica matrix.