Magnetic Media

2015.03.31 Update

Magnetic Media

To meet the demand for increased storage density, the composition of hard disks and tapes has moved to thinner and thinner layered structures. Surface analysis techniques are ideally suited to characterize the nanometer protective coatings and magnetic layers that make up today’s magnetic media. In addition to characterizing the magnetic media, the use of surface analysis equipment plays a key role in the detection of contaminants on the read/write heads and components throughout the disk drive.

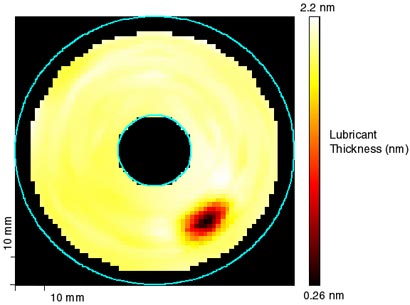

Lubricant thickness measurements (XPS)

XPS surface analysis is the standard laboratory tool for measuring lubricant thickness and composition on hard disk media. A simple non-destructive measurement provides high measurement precision and high sensitivity to small changes in lubricant thickness.

Fig. 1: An XPS lubricant thickness map shows the presence of a void in the 2 nm lubricant coating on a 95 mm diameter hard disk media.

Thin film analysis (XPS, AES, D-SIMS, TOF-SIMS)

Thin film analysis via sputter depth profiling provides a direct means to view the composition and distribution of materials in the complex thin film structures used to manufacture high density storage media. In addition to verifying the presence of the correct thin film structure, contaminants and interdiffusion of layers can be observed.

Fig. 2: An XPS sputter depth profile of a computer hard disk shows the presence of ultra thin protective layers at the surface and the composition of the magnetic layers below.

Molecular identification of lubricants, additives, and contaminants (TOF-SIMS)

TOF-SIMS surface analysis can be used to probe hard disk surfaces to identify the lubricant composition, additives and contaminants that may be present. Mass spectra fragmentation patterns (finger prints) provide a direct means to identify specific organic compounds.

Fig. 3: TOF-SIMS surface mass spectra provide fragmentation patterns that can be used to identify the presence of a specific lubricant, additive, or contaminant.

Micro-contamination and microstructure analysis (TOF-SIMS, AES)

TOF-SIMS and AES surface analysis equipment can be used to detect and characterize micro-area contaminants or patterned features on magnetic media or read/write heads with sub-micron spatial resolution.

Fig. 4: A TOF-SIMS image shows the presence of cobalt at the surface of a disk in texture lines as a corrosion product.